The Introduction to Automatic Battery Systems in poultry

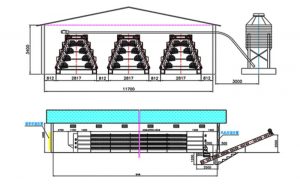

The poultry industry is continually evolving, and one innovation that has gained significant attention is the adoption of automatic battery systems. These systems offer a range of advantages, from increased efficiency to improved animal welfare. However, alongside these benefits come unique challenges that poultry farmers need to address.

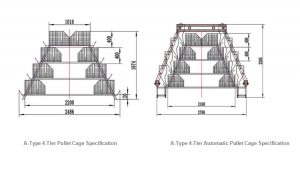

Automatic A-type battery cages:

Layer chickens and pullets use automatic A-type battery cages. A-type battery cages are like a ladder shape. Each layer is symmetrical, with the same number of cages on either side.

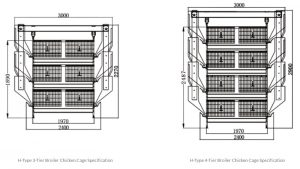

H-type battery cages:

The H-type battery cages are suitable for broilers, pullets, and layer chickens. In general, the vertically stacked cages save more land space; and increase rearing number. Such as H -type broiler cages have the characteristics of high automation, high density, using intensive, high-efficiency feeding management mode.

Advantages of Automatic Battery Systems in Poultry

Boosted Efficiency and Productivity

Automatic battery systems revolutionize poultry farming by streamlining various processes. These systems automate tasks such as feeding, watering, and waste removal, reducing the need for manual labor. As a result, farmers can manage larger flocks with fewer personnel, leading to increased productivity and profitability.

Enhanced Animal Welfare

The well-being of poultry is a top priority, and automatic battery systems contribute to better living conditions for the birds. These systems ensure consistent access to food and water, maintain optimal temperature and lighting, and minimize stress. By promoting a healthier and more comfortable environment, poultry farmers can raise happier and healthier birds.

Precise Data Monitoring

Modern automatic battery systems are equipped with advanced sensors and data collection tools. This allows farmers to closely monitor parameters such as feed consumption, egg production, and environmental conditions. With real-time insights, farmers can make informed decisions to optimize their operations and respond promptly to any issues.

Space Optimization

Automatic battery systems make efficient use of space, a crucial consideration for poultry farming. These systems are designed to maximize vertical space, allowing farmers to accommodate more birds within a compact area. As land becomes scarcer and more expensive, this space-saving feature is invaluable for sustainable and profitable farming.

Reduced Feed and Water Waste

Traditional feeding methods can lead to significant feed and water wastage. Automatic battery systems address this issue by delivering precise portions of feed and water directly to each bird. This not only reduces waste but also contributes to cost savings over time.

Challenges in Implementing Automatic Battery Systems in Poultry

Initial Investment Costs:While automatic battery systems offer long-term benefits, the initial investment can be substantial. Setting up the necessary infrastructure, purchasing equipment, and integrating automation technology requires a financial commitment that may be challenging for some farmers.

Technical Expertise:Operating and maintaining automatic battery systems demand a certain level of technical proficiency. Farmers must be well-versed in software management, troubleshooting, and equipment maintenance. Acquiring and retaining such expertise can pose a challenge for those unfamiliar with modern automation technologies.

Power Supply Reliability:Automatic battery systems rely heavily on a consistent and stable power supply. Any disruptions can lead to system failures, potentially affecting bird health and farm operations. Farmers must have backup power solutions in place to ensure uninterrupted functionality.

Maintenance and Repairs:While automatic systems reduce the need for manual labor, they do require regular maintenance and occasional repairs. Farmers need to establish a maintenance schedule and have access to reliable technical support to address any issues promptly.

How to Choose the Right Poultry Battery Cage

Selecting the optimal poultry battery cage is a critical decision that can significantly impact the success of your poultry farm. Here are key factors to consider:

Cage Design and Layout:Evaluate different cage designs and layouts to determine which one best suits your farm’s needs and available space. Consider factors such as bird density, ventilation, and ease of cleaning.

Quality and Durability:Invest in high-quality battery cages that are built to withstand the rigors of poultry farming. Durable materials and well-constructed designs ensure longevity and a better return on investment.

Automation Features:Examine the automation features offered by different battery cage systems. Look for options that align with your farm’s requirements, whether it’s automated feeding, egg collection, or waste removal.

Compatibility with Technology:Ensure that the chosen battery cage system is compatible with your existing technology infrastructure. Seamless integration between automation systems and data management tools is essential for efficient operations.

Cost-Benefit Analysis: Conduct a thorough cost-benefit analysis to determine the long-term financial impact of the chosen battery cage system. Consider factors such as initial investment, operational savings, and potential productivity increases.

Manufacturer Reputation: Choose a reputable and established manufacturer with a track record of delivering reliable and innovative battery cage solutions. Research customer reviews and seek recommendations from fellow poultry farmers.

FAQs about Automatic Battery Systems in Poultry

What are h-type battery cages, and how do they differ from other cage designs?

H-type battery cages are a specific type of poultry housing that allows for vertical stacking of cages. This design optimizes space utilization and facilitates automated feeding and egg collection. It differs from other cage designs by offering greater vertical capacity and efficient resource management.

Are automatic battery systems suitable for small-scale poultry farms?

Yes, automatic battery systems can be adapted for small-scale poultry farms. While the initial investment may be higher, the increased efficiency and reduced labor requirements can still offer significant benefits, making it a viable option for smaller operations.

How do automatic battery systems contribute to sustainability?

Automatic battery systems enhance sustainability by minimizing resource wastage, optimizing space usage, and reducing the ecological footprint of poultry farming. By efficiently managing feed, water, and energy consumption, these systems contribute to a more environmentally responsible industry.

Can automatic battery systems be customized to meet specific farm needs?

Yes, many automatic battery system manufacturers offer customization options to tailor the system to the unique requirements of each farm. This flexibility ensures that farmers can choose the features and functionalities that align with their production goals and operational preferences.

What role does data monitoring play in automatic battery systems?

Data monitoring is a crucial aspect of automatic battery systems. Advanced sensors collect real-time data on various parameters, allowing farmers to make informed decisions for optimal flock management. Monitoring feed consumption, egg production, and environmental conditions helps maximize productivity and animal welfare.

How can farmers address the challenges of technical expertise?

Farmers can overcome the challenge of technical expertise by investing in training and education. Attending workshops, seeking guidance from experts, and collaborating with technology providers can help farmers develop the necessary skills to operate and maintain automatic battery systems effectively.

The integration of automatic battery systems in poultry farming offers a range of advantages, from improved efficiency to enhanced animal welfare. While challenges such as initial investment costs and technical expertise must be addressed, the potential benefits make these systems a compelling option for modern poultry farmers. By carefully selecting the right poultry battery cage and leveraging advanced automation technologies, farmers can achieve sustainable and profitable operations in the ever-evolving poultry industry.

If you need chicken farm equipment, please contact us!