In the heart of Kenya’s bustling poultry industry, the choice of housing for your laying hens can make all the difference. Introducing the unparalleled solution: 4-tier A-type layer cages, meticulously designed to accommodate 160 laying hens while optimizing space, ensuring bird welfare, and enhancing productivity.

Why Choose 4 Tier A-Type Layer Cages for 160 Laying Hens?

In the dynamic landscape of poultry farming, strategic decisions can shape the destiny of your operation. Here’s why opting for our 4 tier A-type layer cages is a game-changer:

- Space Optimization and Efficiency: Our 4-tier A-type layer cages redefine spatial dynamics. With an ingenious tiered layout, you unlock the potential to house 160 laying hens without compromising their freedom of movement. Embrace efficiency to help you obtain more profit.

- Low broken egg rate: After a lot of experiments and breeding experience, our bottom mesh tilt Angle is 7° which is more suitable for layer breeding and greatly reduces the broken egg rate.

- Health and Hygiene Simplified: Cleanliness is paramount in poultry farming. Our cages are engineered for easy maintenance, promoting a hygienic environment that safeguards your flock from diseases. Minimize risks and nurture healthier laying hens.

- lifetime of up to 15-20 years: The layer cages mesh is Q235 international steel wire with high hardness. Cages mesh uses high tensile strength and the material of cage mesh adopts a hot dip galvanizing process that is generally 3-4 times the service life of could galvanizing and have a lifetime of up to 15-20 years.

- Creating a strong and safe layer cage: the cage mesh welding process adopts automatic welder welding which can reach 500N tension without peeling. Meanwhile, welding is clean without welding slag. High welding strength and no solder joints, will not scratch the chicken.

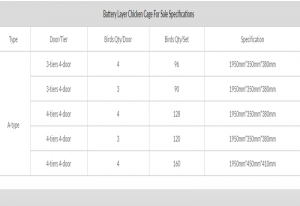

The specification of 4 tier A-type layer cages for 160 laying hens in Kenya

4-tier A-type layer cages for 160 laying hens have the characteristics of simple structure, easy operation, and maintenance, high -selectivity of automation equipment, low investment cost, fast income, and so on. That can be based on different requirements of users to create.

|

type |

Model |

Birds qty/door |

Birds qty/set |

specification |

|

A-type |

4-tier 5-door |

4pcs |

160pcs |

1950*450*410 |

- Cage Material: The layer cages are made of hot dip galvanized and corrosion-resistant.

- Cage Dimensions: Each cage unit boasts dimensions carefully calibrated for comfort and performance.

- Feeding System: Precision-designed feeders minimize wastage and ensure a consistent supply.

- Drinking System: Automated water delivery guarantees a steady flow of clean water for your 4 Tier A-Type Layer Cages for 160 Laying Hens.

- Egg Collection: Ingenious collection mechanisms make harvesting eggs effortless.

- Waste Management: Thoughtfully integrated trays simplify waste removal, promoting cleanliness.

A Successful Project of 4 Tier A-Type Layer Cages for 160 Laying Hens in Kenya

Kenya, a prosperous and diverse country, presents opportunities and potential in the agricultural and food industries. In Kenya, many restaurant owners aspire to be self-sufficient by producing fresh ingredients to meet the demands of the food supply chain.

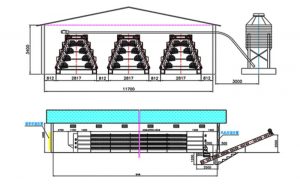

This case study depicts how a restaurant owner in Kenya fulfilled his requirement of rearing 20,000 chickens by purchasing 125 sets of 4 Tier A-Type Layer Cages for 160 Laying Hens. These cages offer adjustable space and environment, suitable for large-scale production, and optimize the rearing process to enhance production efficiency.

Jeffrey, an entrepreneur in the restaurant industry, provides a variety of delicacies at his establishment. However, due to the growing market demand, he chose livi poultry farming equipment with about 4 Tier A-Type Layer Cages for 160 Laying Hens.

Several months later, Jeffrey witnessed substantial returns on his investment. His poultry farm began producing a significant quantity of fresh eggs daily, providing a consistent supply for his restaurant. The freshness of the eggs added a unique flavor to his culinary offerings, attracting customers and enhancing his business reputation.

5 Tips for Selecting the Ideal Layer Cages

Navigating the array of options demands insight. Here are five invaluable tips to guide your choice:

- Assess Your Space: Understand your available space and choose a solution that optimizes it, just as our 4-tier A-type layer cages do.

- Prioritize Bird Welfare: Happy hens are productive hens. Opt for cages that offer ample room for movement and nesting.

- Quality Matters: Invest in durability. Select cages crafted from superior materials like our galvanized steel.

- Streamlined Cleaning; Efficiency in maintenance is key. Look for cages designed for easy cleaning and waste removal.

- Customization for Your Farm: Every farm is unique. Choose cages that can be tailored to your specific needs, enhancing your operation’s efficiency.

Choose 4 Tier A-Type Layer Cages for 160 Laying Hens in Kenya

As you embark on this pivotal journey in poultry farming, the choice is clear: our 4-tier A-type layer cages empower you to elevate your operation beyond expectations. Witness enhanced egg production, optimal space utilization, and the contentment of your hens. Make the move that sets you on the path to unparalleled success.

For more details, inquiries, and orders, please contact us!