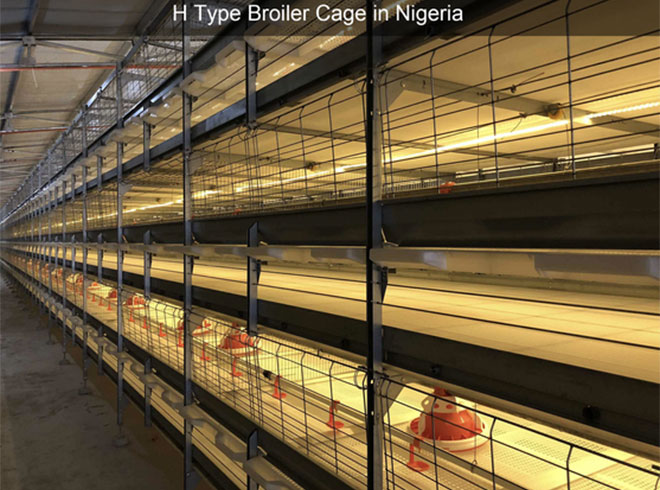

Poultry farming is a thriving industry across the globe, and for farmers aiming to scale up, investing in the right broiler chicken equipment can make all the difference. The H-type broiler cage battery cage system from LIVI Poultry Equipment Manufacturer offers a robust chicken farm solution, blending durability, efficiency, and automation to maximize productivity. This project case sharing explores how a 20,000-broiler farm can leverage this system, provides a step-by-step guide to acquiring it, and showcases a real customer success story from Nigeria.

Why Choose the H-Type Broiler Cage System?

The H-type broiler chicken cage is a game-changer for large-scale poultry operations. Designed for intensive farming, it optimizes space, reduces labor, and ensures healthy broiler growth. LIVI’s system comes in two configurations:

-

3-Tier 2-Door broiler cage: 18 cages per set, holding 216 birds, dimensions 2000mm*1800mm*450mm, with 500cm² per chicken.

-

4-Tier 2-Door broiler cage: 19 cages per set, holding 304 birds, dimensions 2412mm*1600mm*500mm, with 508cm² per chicken.

Crafted from International Q235 steel with aluminum-zinc alloy and hot-dip galvanized anti-corrosion treatment, these broiler battery cage equipment systems promise a lifespan of 15-20 years. Paired with automation auxiliary equipment—automatic feeding, manure cleaning, environmental control, and drinking water systems—this setup is ideal for a 20,000-bird farm aiming for efficiency and profitability.

Step-by-Step Guide to Acquiring H-Type Broiler Cage Systems from LIVI

Investing in a chicken cage system for sale can transform your poultry business, but the process requires careful planning. Here’s how to secure the best broiler chicken equipment from LIVI Poultry Equipment Manufacturer:

-

Assess Your Farm’s Needs

Start by evaluating your farm size, budget, and goals. For a 20,000-broiler operation, calculate the number of cage sets needed. The 3-tier broiler cage system holds 216 birds per set (92 sets for 19,872 birds, plus extras), while the 4-tier holds 304 birds per set (66 sets for 20,064 birds). Factor in space—e.g., a 105m*15m house fits the 4-tierbroiler cage system layout comfortably. -

Research LIVI’s Offerings

Visit LIVI’s website or contact their team to explore the H-type broiler chicken cage specs. Request detailed brochures on the 3-tier and 4-tier options, focusing on automation features like manure cleaning and environmental control. LIVI offers free chicken house design based on your land dimensions. -

Request a Quote

Submit an inquiry with your farm details—bird capacity, house size, and automation preferences. LIVI provides customized quotes, often including shipping costs to your location. For a 20,000-bird farm, expect a mix of cages and auxiliary equipment tailored to your needs. -

Confirm Specifications and Customization

Verify the cage specs: Q235 steel, 500-508cm² per bird, and anti-corrosion treatment. Discuss automation add-ons—automatic feeding saves labor, while ventilation systems ensure bird health in tough climates. LIVI allows tweaks to suit your farm’s layout. -

Place the Order and Arrange Payment

LIVI typically requires a 30% deposit via T/T or Western Union, with the balance due before shipping. For a 20,000-bird setup, costs might range from $50,000-$80,000, depending on automation levels. Confirm delivery timelines—usually 4-6 weeks. -

Installation and Support

Once delivered, LIVI provides installation guidance or on-site support if requested. Their team ensures the broiler battery cage equipment integrates seamlessly with automatic feeding, drinking water, and manure cleaning systems. Post-installation, they offer maintenance tips to maximize the 15-20-year lifespan.

This process ensures you get a chicken farm solution that fits your operation like a glove, boosting efficiency and profits.

Real Customer Case: Scaling to 20,000 Broilers in Nigeria

Meet Adebayo, a poultry farmer from Ogun State, Nigeria, who transformed his business with LIVI’s H-type broiler cage system. Starting with 5,000 broilers in traditional floor pens, Adebayo faced high labor costs, inconsistent growth rates, and space constraints. In 2023, he decided to scale to 20,000 birds and partnered with LIVI for a modern solution.

-

Project Overview:

Adebayo’s farm spans a 110m16m house, ideal for the 4-tier H-typebroiler chicken cage system (2412mm*1600mm*500mm, 304 birds per set). He ordered 66 sets, housing 20,064 broilers, with each bird enjoying 508cm² of space. The setup included full automation: automatic feeding, manure cleaning, ventilation systems, and drinking water equipment. -

Implementation:

After contacting LIVI, Adebayo received a free house design and a $65,000 quote, covering cages and automation. He paid a 30% deposit, and the equipment arrived in Lagos six weeks later. LIVI’s team assisted with installation over two weeks, integrating the automatic feeding system (conveyor belts delivering precise feed) and water filtration systems (nipple drinkers for clean water). The manure cleaning belts, running under each tier, kept the shed hygienic, while environmental controls maintained 26-28°C—perfect for Nigeria’s humid climate. -

Results:

Within the first 7-week cycle, Adebayo saw stunning outcomes. His 20,000 broilers reached an average weight of 2.5kg, up from 2.2kg in floor pens, thanks to consistent feeding and ventilation. Daily labor dropped from 10 workers to 3, saving $1,200 monthly. Mortality fell from 8% to 3%, and he harvested 19,400 birds, netting $97,000 at $5 per bird—$20,000 more than his old system. “The H-type broiler chicken cage turned my farm into a machine,” Adebayo says. “It’s tough, efficient, and built for Nigeria’s heat.” -

Long-Term Impact:

A year later, Adebayo’s profits have doubled, and he’s planning to add another 10,000 birds. The Q235 steel and hot-dip galvanized finish show no rust, promising years of use. The automation—especially manure cleaning and environmental control—has made his farm a local benchmark.

Why It Works for Africa’s Tough Conditions

Africa’s climates test any equipment. The broiler battery cage equipment from LIVI, with its aluminum-zinc alloy and galvanized treatment, resists corrosion in humid zones like Nigeria or dusty regions like Kenya. The 500-508cm² per bird ensures comfort, while ventilation systems combat heat stress—vital for a 20,000-bird farm. Automatic feeding and drinking water systems cut waste, and manure cleaning keeps disease at bay, making this a chicken farm solution tailored for the continent.

Scaling Your 20,000-Bird Dream

For a 20,000-broiler farm, the H-type chicken cage system delivers. The 4-tier setup (66 sets) fits neatly into a 105m*15m house, while the 3-tier (92 sets) suits slightly larger spaces. Automation slashes labor by 70%, and the 15-20-year lifespan ensures long-term value. At $5 per bird, a single cycle could yield $97,000-$100,000, with costs recouped in 2-3 years.

Ready to boost your farm? Contact LIVI Poultry Equipment Manufacturer, spec out your H-type broiler chicken cage, and join farmers like Adebayo in turning 20,000 broilers into a thriving business. Africa’s poultry future is here—built tough, smart, and profitable.