In March 2023 we provided John with 180 sets of 4-tier A-type layer cages for 30,000 in South Africa. Using our 4-tier A-type layer cages, John successfully started his chicken farming business.

Successful 4-tier A-type layer cages for 30,000 Projects in South Africa

Background information: South Africa is a rapidly developing country in agriculture, and the poultry industry is also growing. Layer farming is one popular method as it provides a stable source of income. John, a farmer in South Africa, operates a poultry farm. To expand and increase production, he decided to purchase a certain number of layer cages.

Customer requirements: The poultry house has an area of 1500 square meters, with a length of 100 meters and a width of 15 meters. John wants to raise 30,000 layers and is looking for suitable layer cages to accommodate more chickens and increase the farm’s production and profits. He wants the cages to be of high quality, durable, and easy to clean to ensure the comfort and health of the layers.

Confirmation of requirements: John had a detailed discussion with a sales representative from a poultry equipment company, explaining his requirements and budget.

Solution provided: We recommended A-type four-tier five-door layer cages for John, and based on his farming capacity, we suggested 188 sets of cages and provided a quotation. The quotation includes the design, dimensions, materials, and prices of 180 sets of layer cages, as well as an estimated delivery time.

By purchasing our layer cages, John successfully expanded his poultry farm and raised around 30,000 layers. The egg production also significantly increased, leading to higher profits and a thriving poultry business for John.

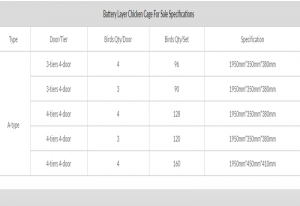

The specification of layer cages

The automatic A-type chicken layer cages are like a ladder shape. Each layer is symmetrical, with the same number of cages on either side. The structure is stable and generally has 3 or 4 tiers. It has the characteristics of simple structure, easy operation, and maintenance, high -selectivity of automation equipment, low investment cost, fast income, and so on.

Why choose 4-tier A-type layer cages for 30,000 chicekns?

- Creating a strong and safe layer cage: The cage mesh welding process adopts automatic welder welding. That can reach 500N tension without peeling. Meanwhile, welding is clean without welding slag. High welding strength and no solder joints, will not scratch the chicken.

- Low broken egg rate: After a lot of experiments and breeding experience. Our bottom mesh tilt Angle is 7° which is more suitable for layer breeding and greatly reduces the broken egg rate.

- lifetime of up to 15-20 years: The layer cages mesh is Q235 international steel wire with high hardness. Cage mesh uses high tensile strength. The material of cage mesh adopts a hot dip galvanizing process. That is generally 3-4 times the service life of could galvanizing and have a lifetime of up to 15-20 years.

-

Creating a strong and safe layer cage: The cage mesh welding process adopts automatic welder welding which can reach 500N tension without peeling. Meanwhile, welding is clean without welding slag. High welding strength and no solder joints, will not scratch the chicken.

livi poultry farming equipment has 25 years of expertise in the poultry farming industry. The company’s business covers more than 80 countries and regions around the world. We offer poultry farm cages consisting of layer, broiler, and chick and we offer automatic poultry farm equipment. One-stop to meet your need.

livi poultry farming equipment is a good choice, please contact me!